High efficiency white LEDs have advanced to the point where they can replace glow bulbs and other light sources not only as indicators, but also for illumination. While many of the claims made about the LEDs' efficiency, light quality, lifetime and economy are mostly exaggeration, the truth is that for very low light levels they are now competitive. They have equal or slightly higher efficiency than a flashlight bulb, a longer lifetime, and are very much tougher. On the other hand, they are still far more expensive than a bulb, for a given light output.

It follows that LEDs are almost ideal for very tiny, low power flashlights, in the less-than-one-watt category. But such a low power flashlight makes sense only if the whole flashlight is small and lightweight, and has a reasonable battery lifetime. But white LEDs require about 3.3 volts each, and typically some extra voltage is needed to provide room for current regulation! That's why most commercial LED flashlights use at least three alkaline or NiMH cells, or a lithium cell. And often they can't use their batteries all the way down to the true end of their charges!

Using three AA cells isn't really practical for a small flashlight, simply because it will no longer be small! Lithium cells are expensive. So some manufacturers use three button cells, but these last only for minutes and are also expensive compared to their tiny energy contents! So I set out to build a circuit that lights a string of white LEDs, using a single alkaline or NiMH cell. That allows using the widely available and inexpensive AA cell, obtaining a small size, low cost and good runtime.

A typical white LED has its best power-efficiency combination at about 20mA, and needs about 3.3V. This makes for a power of about 66mW per LED. I decided to use seven LEDs, because they can be arranged in a nice and compact way with one in the middle and the other six around, and the whole array runs at close to one half watt, which is a reasonable power for a tiny pocket flashlight. To avoid having to control the current separately for each LED, the LEDs were arranged in series. So, I needed a driver circuit that will provide about 23V at 20mA, when fed from a 1.2V NiMH rechargeable cell or from a 1.5V alkaline cell. It should be ultra simple, low cost, efficient and reliable. And here it is!

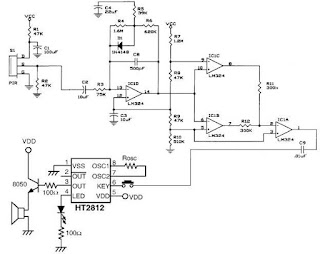

The circuit is a self-oscillating boost converter, and I certainly cannot claim having invented it. It is ages old! I only did the detail design of this one, and optimized it in the course of one afternoon. It runs with a beautifully clean waveform, with all components except the LEDs staying completely cold to the touch. At this low power level, even that doesn't guarantee a good efficiency, but I measured it at about 72%, which is quite good for a circuit operating from such a low voltage!

How it works:

When switching it on, R1 and D1 bias the transistor into the linear range, through the feedback winding on T1. That causes a current through the 18 turn winding, and thanks to the positive feedback the transistor is driven into saturation. At this moment there will be a base current defined like this: The 1.2V of the cell, plus the 0.2V induced in the feedback winding, minus the 0.7V base-emitter drop of the transistor, make a total of 0.7V, which applied to the 22 ohm resistor gives about 32mA base current. D1 is not conducting a significant current at this time, because the transistor clamps the base voltage to 0.7V and the 3 turn winding subtracts 0.2V from this, so that we end up with only 0.5V across the diode.

This base current keeps the transistor in saturation until its collector current reaches approximately 1A, while the transformer loads up. At this point the transistor will start getting out of saturation, which makes the feedback voltage drop. This very quickly puts the transistor into blockage. The collector voltage will soar as T1 forces current to keep flowing, until D2 starts conducting and discharges the transformer into C2, by means of a quite narrow pulse. During operation this pulse is about 24V high, so that the feedback winding develops -4V, which results in applying about -3.3V to Q1's base, enough to switch it off very fast, but not enough to make the base reverse-conduct.

As soon as the transformer has fully discharged into C2, the voltage on it breaks down, and the transistor enters conduction to start a new cycle. The oscillating frequency is 30kHz, and the transformer operates at a peak flux density of 0.1 tesla, far away from saturation, and low enough to have very low loss. C2 has to eat the load pulses that start at about 1A, and has to keep the voltage constant enough to feed the LEDs an almost smooth DC. The value given works well. If anyone wants to build this circuit to run 24 hours a day for 30 years, it would be good to pick a capacitor rated for low ESR and a relatively high ripple current, but for flashlight use a plain standard 47µF, 35V electrolytic capacitor works great.

C1 is not strictly necessary. With a good NiMH cell, the circuit works the same without it, so you can save a few cents here. But with the capacitor in place, the circuit keeps working better when the cell is almost fully discharged and its internal resistance gets higher, so it's better to include it.

Components:

Of course, the part over which most builders will stumble is the transformer. I used an Amidon EA-77-188 core, because I had it at hand, and it was the smallest core I had. I should say that this core is still at least five times larger than required! So feel free to use the smallest ferrite double-E core you can find, or any other ferrite core that offers a closed loop and the possibility of assembling it with an air gap. But then you will have to redo the math!

The main winding has 18 turns, and I wound it with 7 strands of #30 enameled wire twisted together, simply because there is room enough to do so. But this thick wire bundle is huge overkill, like the whole transformer is! The feedback winding was wound with a single strand of that same #30 wire, and it has just three turns. The phasing is like shown in the diagram, of course. If you get the phasing wrong, the circuit won't work and the transistor will get warm.

I used masking tape to hold the windings in place on the bobbin. No special insulation is required, because the voltages are so low that the enamel on the wire is insulation enough.

Now comes a very important step: This transformer is airgapped. The two core halves need to be separated by a distance of 0.1mm. I simply stuck little pieces of masking tape on the three legs of one core half, taking advantage of the fact that my masking tape is just the right thickness! Then I assembled the core, wrapping masking tape around it to hold it together.

If you have to use a different ferrite core, you can use my transformers and coils article to learn how to design your transformer. The turns ratio will of course remain 6:1, but the absolute number of turns will change in inverse proportion to the core's cross section. You can look up the data of my core on Amidon's or Bytemark's websites, compare that to the data for your core, and go from there. After calculating the turns numbers, you have to calculate the required air gap to obtain an inductance of the main winding of about 40µH.

The transistor I used, the 2SC1226A, is a pretty old part and may no longer be available. I have a bunch of them, so I used it. It has a soft, thin copper tab which can easily be cut off, which is an advantage in this circuit, because it allows saving some space! The transistor works cold, so it doesn't really need the tab! If you have to use another transistor instead, feel free, but look for one which has the proper characteristics: It should have a breakdown voltage of about 40V, a maximum continuous current of about 3A, be reasonably fast (mine is very fast, having an Ft of 150MHz!), it should have good saturation characteristics, and it should have a reasonably high hfe (at least 30, ideally about 100) at a current of 1A.

Any different transistor will most likely require a change in the value of R1, to set the proper power level for the LEDs. You can experimentally determine that resistor value, by placing a milliamperemeter in series with the LED string, and selecting the resistor for 20mA in the LEDs. By the way, if you want to build this circuit for an alkaline cell instead of a NiMH cell, the resistor should be a bit higher. D2 is a Schottky rectifier. A non-Schottky ultrafast diode could be used too, but the Schottky is better. D1 instead is any plain simple silicon diode.

If your power switch doesn't have very low resistance, it might cause a significant loss in this low voltage circuit! If that happens, you could instead place the power switch in series with R1, leaving the rest of the circuit permanently energized. That will cost almost no lost battery power, because the only current drain when off will be the leakage through the parts, which should be in the microampere range. But if you place the switch at R1, you should also place a 1 megaohm resistor (or almost any other high value) in parallel with D1, to make sure that the transistor really does stay fully off when it should!